Ang email dili mahimong walay sulod

Ang password dili mahimong walay sulod

Sayop sa format sa email

Ang email dili mahimong walay sulod

Anaa na ang email

6-20 ka karakter (mga letra ug numero lamang)

Ang password dili managsama

Sayop sa format sa email

Ang email dili mahimong walay sulod

Wala ang email

6-20 ka karakter (mga letra ug numero lamang)

Ang password dili managsama

Balita

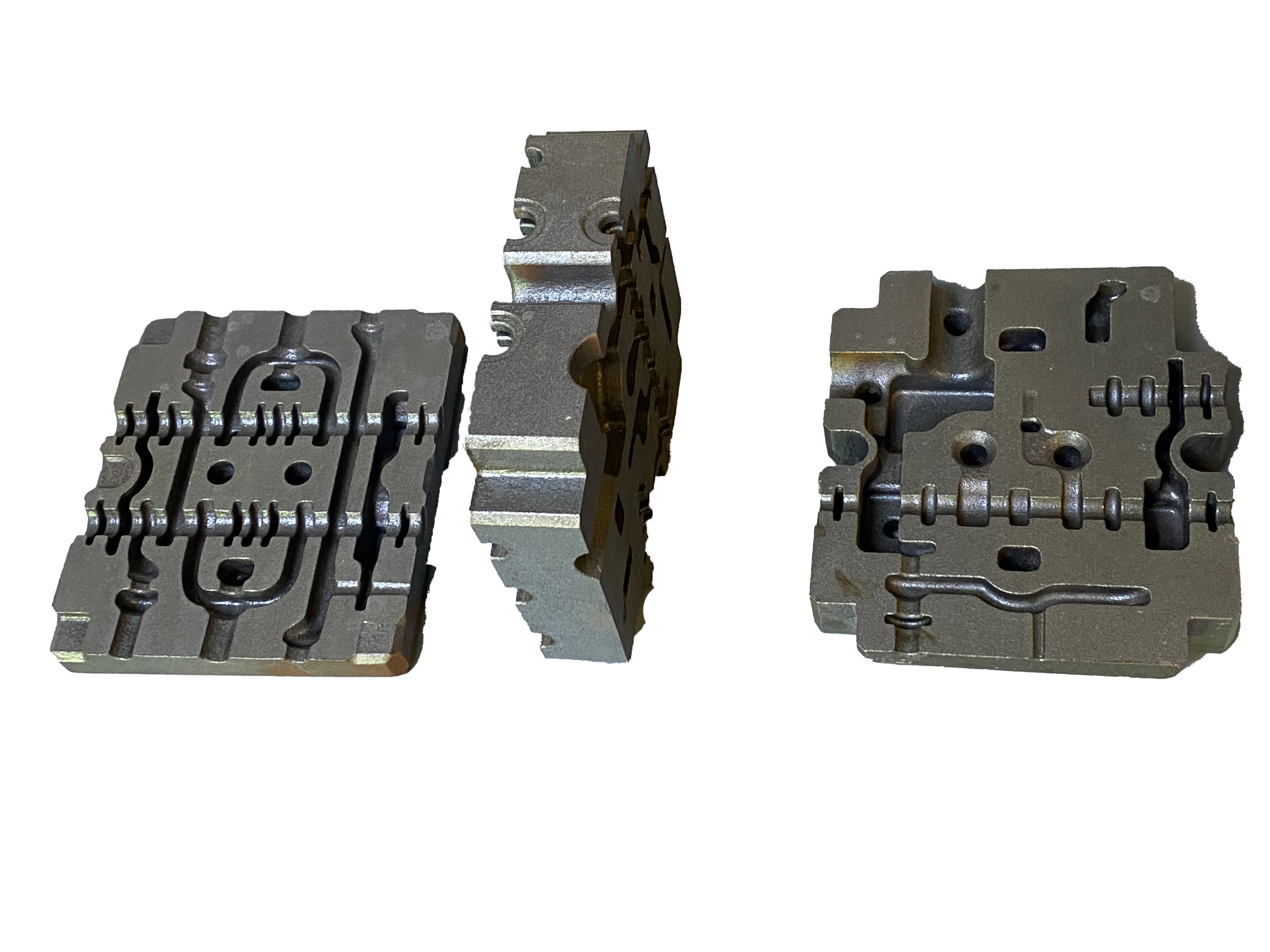

What's the Matter with Pores when Welding Cast Iron?

The main reasons for pores in cast iron welding are as follows:

- There is a lot of oil on the surface of the cast iron matrix. After long-term oil immersion, and the cast iron structure is relatively loose, it is easy to have oil, so when it is heated during welding, the oil burns, and black smoke will be mixed into the welding pool.

Solution: preheat before welding to reduce the impact of long-term oil immersion until all the oil stains inside the organization are volatilized and burned at a high temperature.

- When the coating of cast iron electrode is damp, pores are produced during welding.

Solution: the welding rod needs to be preheated and used after being dried in a drying cylinder.

- The quality problem of controlling the impurity content of the cast iron electrode itself leads to a lot of impurities in the weld pool during the welding process, forming pores caused by inclusions.

Solution: the quality of the cast iron electrode itself needs to be professionally controlled and selected. Cast iron electrodes with better quality can be selected.

- The problem with the material of the cast iron matrix itself, is because the material of the cast iron equipment cast in each foundry is different, so when welding, the content of impurities in the cast iron matrix material is too much when passing through the molten pool, there is also a chance of impurities returning to the molten pool to form pores.

Solution: only through welding to produce pores, then grinding, and then overlapping the previous welding spot for welding, this treatment is slow, but the effect is also the best.

Common problems in welding

- White structure after welding

It is generally believed that under the rapid cooling condition of 30-100 ℃ /s, the carbon melted in iron does not have time to precipitate in the form of graphite, but appears as cementite, that is, the so-called white mouth. The white structure is hard and brittle, which makes the weld difficult for the machine after welding, and even leads to cracking.

Preventive measures:

Preheating before welding and heat preservation after welding; Properly adjust the chemical composition and cooling rate of filler metal; Improve the chemical composition of weld metal.

- Cracks in welded joints

Because the plasticity of gray cast iron is extremely poor, almost no plastic deformation can occur, and the strength is low, so under the joint action of welding stress and casting stress (structural stress), when the local stress is greater than the strength limit, cracks will occur.

Preventive measures:

Using arc cold welding to reduce welding stress

Select welding materials with good plasticities, such as nickel, copper, nickel copper, high vanadium steel, etc. as filler metal, so that the weld metal can relax the stress through plastic deformation and prevent cracks; Stress can be eliminated by hammering the weld to prevent cracks; When the weld is cooled, it can make up the hindered bottom to contract freely, to avoid cracks caused by excessive force.

Adopt the thermal welding method and control the temperature

When the temperature is higher than 600 ℃, due to certain plastic deformation Some internal stresses are eliminated, and thermal stress cracks will not occur when welding above 600 ℃.

Make a purchase of white cast iron, types of cast iron, cast iron skillets from China, you can get them at a good price if you have a large quantity. We hope to be your long-term partner.