Ang email dili mahimong walay sulod

Ang password dili mahimong walay sulod

Sayop sa format sa email

Ang email dili mahimong walay sulod

Anaa na ang email

6-20 ka karakter (mga letra ug numero lamang)

Ang password dili managsama

Sayop sa format sa email

Ang email dili mahimong walay sulod

Wala ang email

6-20 ka karakter (mga letra ug numero lamang)

Ang password dili managsama

Balita

Will Zinc Alloy Die Castings Rust?

Zinc alloy does not rust.

Rust is a chemical reaction that is essentially the oxidation of metals. The most common rust phenomenon is that iron products are exposed to air for a long time, oxidized by oxygen, or eroded into oxides by oxygen elements in the water.

Zinc alloys can only be oxidized. Zinc alloys are corrosion-resistant, have high strength, and have a low boiling point. It is easy to react with oxygen in the air for a long time to form a dense oxide film on the surface of the alloy to protect the internal metal from further oxidation. To remove reducing substances, the oxide film on the surface can be neutralized with an acidic (such as hydrochloric acid) solution.

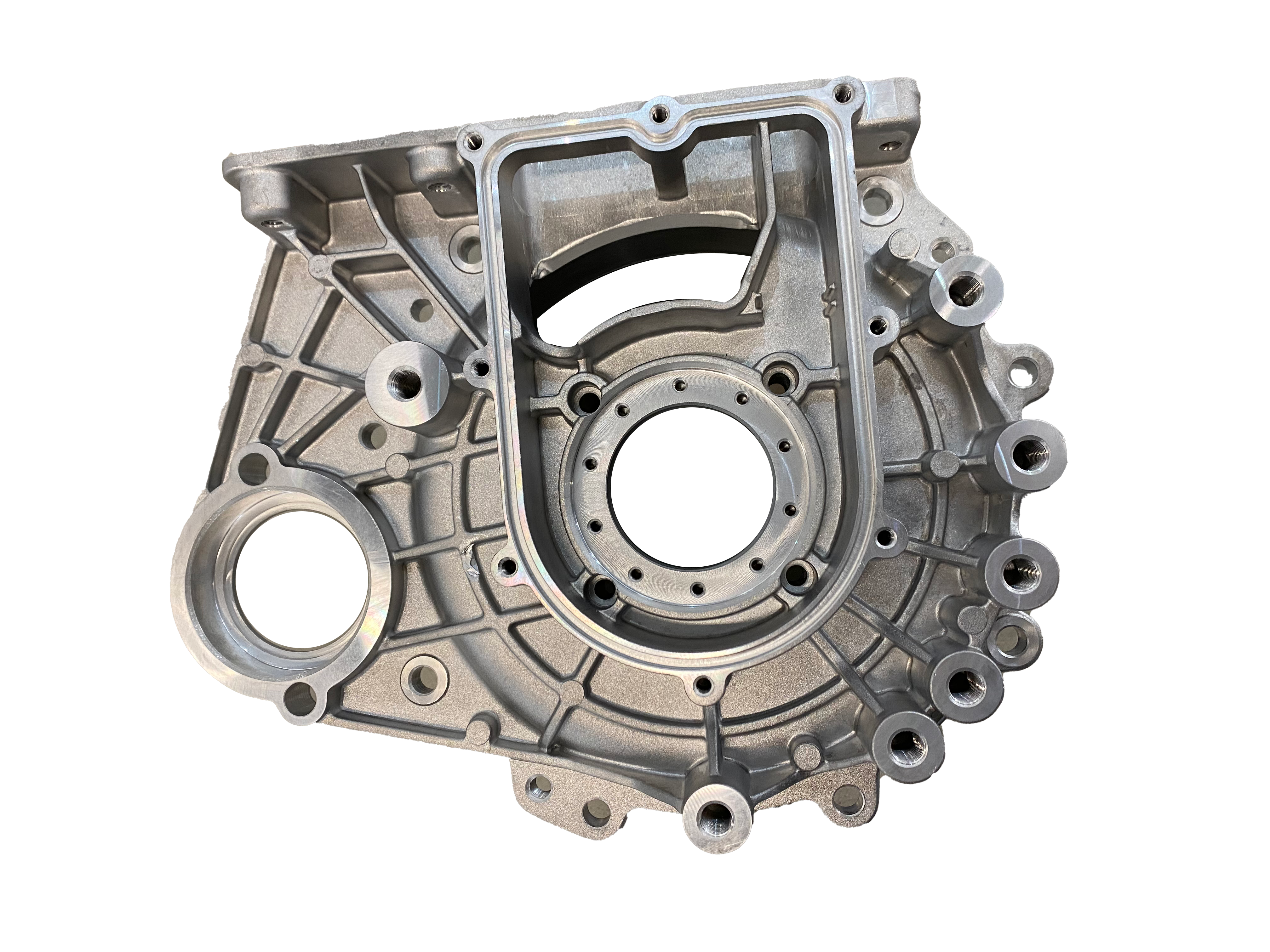

According to the manufacturing process, it can be divided into cast zinc alloy and deformed zinc alloy. The main additives of zinc alloys are aluminum, copper, and magnesium. According to the processing technology, zinc alloys can be divided into deformed and cast zinc alloys. Cast zinc alloys have good fluidity and corrosion resistance. Suitable for die-casting equipment, auto parts casings, etc.

Matters needing attention when using zinc alloys:

Poor corrosion resistance

When impurity elements such as lead, cadmium, and tin exceed the alloy composition standard, the casting will age and deform, which is characterized by volume expansion, a significant decline in mechanical properties, especially plasticity, and even cracking for a long time.

The solubility of lead, tin, and cadmium in zinc alloys is very small, so they concentrate on grain boundaries and become cathodes. The aluminum-rich solid solution becomes the anode, promoting interparticle electrochemical corrosion in the presence of water vapor (electrolyte). Die castings are aging due to intergranular corrosion.

Aging effect

The structure of the zinc alloy is mainly composed of a zinc-rich solid solution containing aluminum, copper and zinc. Their solubility decreases with decreasing temperature. However, due to the fast solidification rate of die castings, the solubility of solid solutions is very saturated at room temperature. After a certain period of time, this supersaturation phenomenon will gradually ease, and the shape and size of the casting will change slightly.

Zinc alloy die castings should not be used at high and low temperatures (below 0°C). Zinc alloys have good mechanical properties at room temperature. However, the tensile strength at high temperature and the impact strength at low temperature decreased significantly.

Due to insufficient clamping force, poor clamping, insufficient mold strength, and excessively high melting temperature, the surface of zinc alloy castings will burst. This phenomenon, known as the product cloak, is often a post-processing process that businesses have to face. It is mainly solved by hand grinding, hydrogen-oxygen explosion, and Zhaoling freeze blasting machine according to the nature of the product.

Zinc alloys do not contain iron, so they do not rust. Details are as follows:

- Zinc alloy will be oxidized because its raw material contains aluminum, but this oxidation will only produce an oxidation reaction on the original embryo. It will be polished and coated effectively by die casting and will be bright and shiny without oxidation.

- Zinc alloys are alloys composed of zinc and other elements. Low-temperature zinc alloys such as aluminum, copper, magnesium, cadmium, lead, and titanium are usually added. Zinc alloys have a low melting point, good fluidity, easy welding, brazing and plastic processing, corrosion resistance in the atmosphere, and easy recovery and remelting of residual materials. Fusion methods, die casting or pressure processing into materials. According to the manufacturing process, it can be divided into cast zinc alloy and deformed zinc alloy.

- The main additive elements of zinc alloys are aluminum, copper and magnesium. According to the processing technology, zinc alloys can be divided into deformed and cast zinc alloys. Cast zinc alloy has good fluidity and corrosion resistance, and is suitable for die-casting instruments, auto parts casings, etc.

Conclusion

For more information about automotive aluminum die casting,die casting metal parts,aluminum precision die casting, we are glad to answer for you.