Ang email dili mahimong walay sulod

Ang password dili mahimong walay sulod

Sayop sa format sa email

Ang email dili mahimong walay sulod

Anaa na ang email

6-20 ka karakter (mga letra ug numero lamang)

Ang password dili managsama

Sayop sa format sa email

Ang email dili mahimong walay sulod

Wala ang email

6-20 ka karakter (mga letra ug numero lamang)

Ang password dili managsama

Balita

The Importance of CNC Machining in Manufacturing Electronic Housing

Due to its high quality and durability, the rugged CNC electronic equipment housing can help achieve this goal easily. Since the shell is made of a single metal part, there will be no fracture or wear of joints.

In addition, experts can use aluminum, stainless steel, plastic, and other materials to make a solid waterproof shell suitable for outdoor use.

If you have not purchased durable housing for your electronic products, please carefully consider the following information to understand why CNC processing may be a prudent choice.

Overview of CNC technology

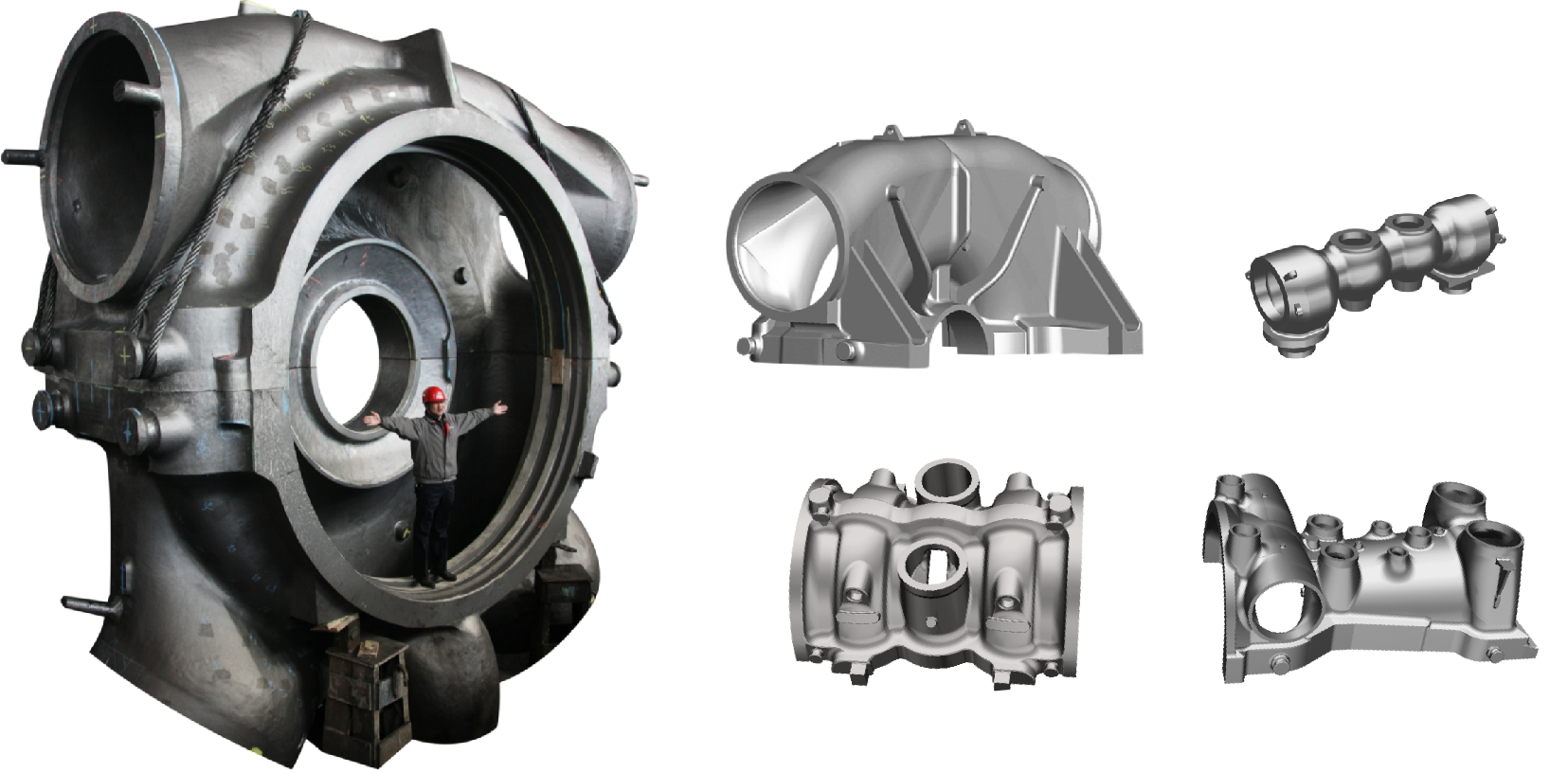

Computer numerical control, usually referred to as CNC machining, is a precision manufacturing technology that can effectively reduce human errors. In this process, engineers use a variety of computer-controlled tools to create and modify various parts, regardless of their complexity. As expected, the global sales of CNC processing tools have been growing in recent years.

The shells and shells made by manufacturers using this technology are more durable than other manufacturing processes such as injection molding or die casting. They can effectively fix the electronic components in the appropriate position, while protecting them from potential damage such as dust, liquid, collision, etc. Therefore, even well-known telephone companies use this method to make solid shells and shells for their equipment.

In addition to electronic enclosures, CNC technology is also widely used in the manufacture of printed circuit boards (or PCBs), semiconductors, sockets, radiators, and connectors.

The type of shell you can consider buying

You can choose from a variety of electronic housings manufactured using CNC methods. Please refer to the following list to find out what you can consider investing in.

Die-cast aluminum - the shell made of this material can be waterproof or waterproof and is used for different purposes in various industries. Rich materials provide natural EMI/RFI protection components, making them suitable for different applications without any trouble.

The dust-proof and waterproof model is very suitable for heavy outdoor use, enabling buyers to shield various electronic products.

Waterproof plastic - this option can be selected by those who need a solid shell for indoor use because it is very convenient and ergonomic. Usually, several people use this box for desktop applications, which need to be beautiful.

They can store all wires consistently and protect them from spillage of water and other liquids. Many manufacturers make them into flame retardants, adding layers of functionality and safety.

Aluminum – the shockproof aluminum model is very popular among many users, making it the most popular model in the industry. These boxes are strong and durable, very suitable for outdoor rough use, with waterproof and dust-proof functions. You can choose any size and product size, or customize the box according to your specifications.

Waterproof aluminum - those who do not want to invest in plastic materials can choose aluminum models designed for outdoor use. These types are waterproof and weather-resistant, making them very suitable for heavy-duty use in all possible cases.

Where to buy

You can rely on reputable online retailers to provide the highest quality CNC electronic equipment enclosures for your specific needs. Look for suppliers that provide multiple choices, so that you can choose one or more products that meet your requirements. For example, when you choose a reliable online seller, you can buy plastic or aluminum cases in the same place.

In addition to quality and durability, we should also consider the price range of the product to understand whether this transaction is economical for you. Usually, reliable dealers will provide these products at a reasonable price to ensure that most people can afford them. They also sell these boxes wholesale, so that people with important needs can easily buy them at a lower cost.

Finally, it is also recommended to choose a supplier who can customize the shell according to your specific needs to make the product unique and suitable for your requirements. Real dealers can usually order one to twenty shells within two weeks and then ship them to customers at a low cost.

Conclusion

Once you start to rely on CNC processing to meet your electronic housing needs, it may greatly reduce the opportunity to switch to other technologies. Although this option may cost you more money, CNC technology can adapt to complex geometries, creating incredibly strong boxes that last longer than other boxes. It's always worth investing in because you can enjoy it longer than usually expected.

For more information about brass cnc machining, custom cnc machining, aerospace cnc machining, plz feel free to contact us.