Ang email dili mahimong walay sulod

Ang password dili mahimong walay sulod

Sayop sa format sa email

Ang email dili mahimong walay sulod

Anaa na ang email

6-20 ka karakter (mga letra ug numero lamang)

Ang password dili managsama

Sayop sa format sa email

Ang email dili mahimong walay sulod

Wala ang email

6-20 ka karakter (mga letra ug numero lamang)

Ang password dili managsama

Balita

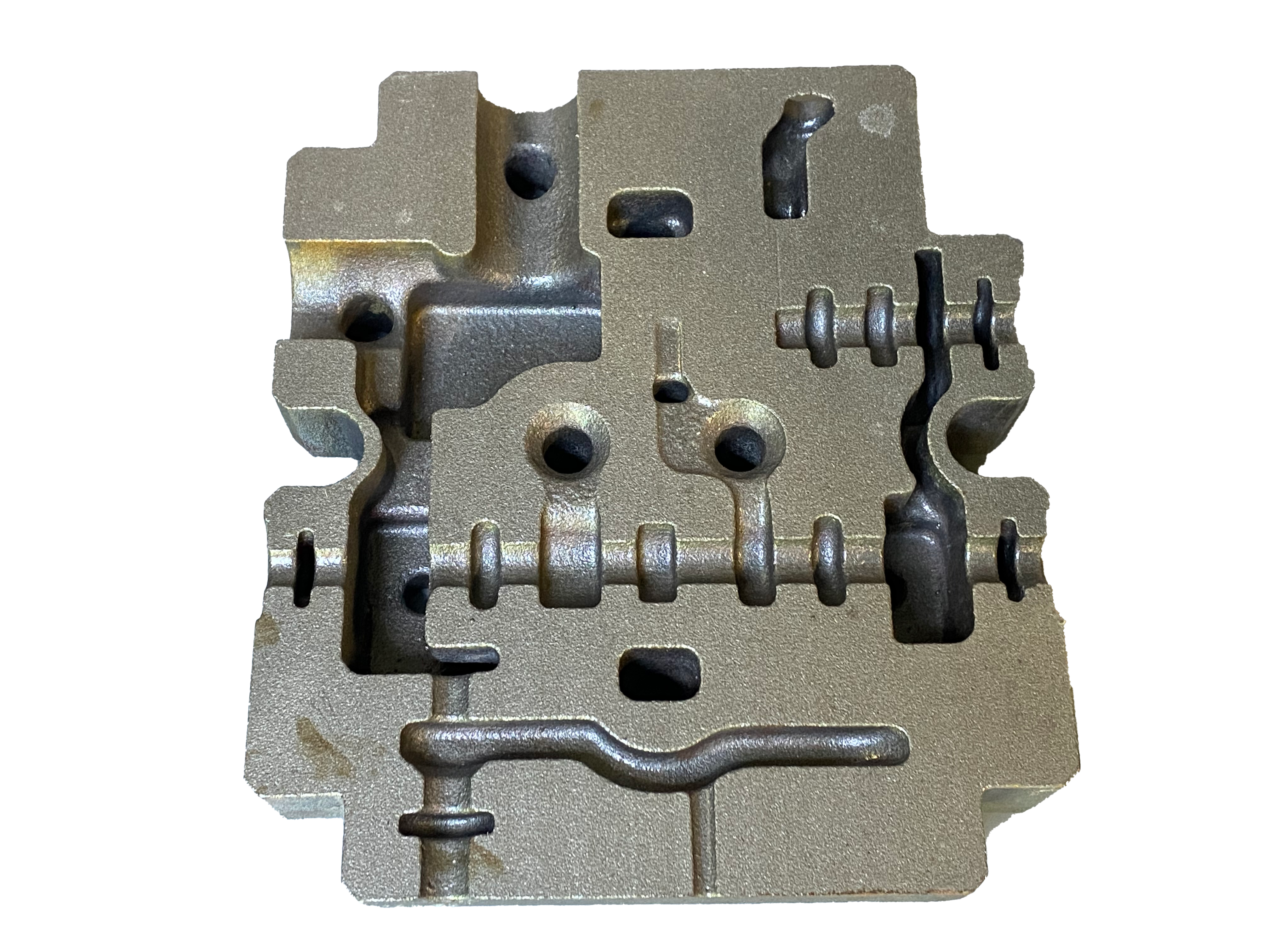

Heat Treatment of White Cast Iron

White cast iron has high hardness, can not be cut, and is very brittle, so it is rarely directly used to manufacture machine parts. Generally speaking, it is very important to choose a reasonable heat treatment process according to the chemical composition and working conditions of cast iron. Generally, the commonly used heat treatment processes are stress relief annealing, softening annealing or normalizing, quenching and tempering, etc. in addition, most white cast iron parts are the blank of malleable cast iron, which need graphitization annealing to decompose most or all of the cementite to form flocculent (or spherical) graphite, Change white cast iron into malleable cast iron.

Stress relief annealing

It is mainly used for high silicon and high chromium alloy white cast iron. Because of the large internal stress in casting, the self-made parts will crack automatically in the process of vibration or environmental changes if the residual internal stress is not eliminated in time. Generally, the annealing heating of iron castings is low, while for high alloy white iron castings, the structure of white iron is relatively stable, so the annealing temperature is high, and the process specification is 800 ~ 900 ℃ × 1 ~ 4h, cooling to 100 ~ 150 ℃ with the furnace after heat preservation, and discharging for air cooling.

Softening annealing

For some alloy white iron castings with high hardenability, there is a large amount of martensite in the cast iron, but there is less cementite and high hardness. The parts made of this kind of material need to be machined, so the softening annealing process must be used to transform martensite into pearlite so that the hardness of the cast iron can be reduced to a machinable level.

Quenching and tempering

It is mainly used for low silicon, low phosphorus, and sulfur wear-resistant white iron castings with low carbon content. Due to its high content of alloy elements, carbides are difficult to dissolve in austenite. Quenching treatment (heating temperature: 950 ~ 1000 ℃) will dissolve more carbides in austenite and obtain a higher hardness martensite structure after cooling, to ensure better wear resistance of cast iron. In order to reduce internal stress and avoid cracking, it can also be quenched in stages with nitrate, and finally tempered for 1 ~ 3H at the temperature of 180 ~ 200 ℃.

Isothermal quenching

It is mainly used for machine plowshares, feed crusher hammers, shot blasting machine blades, lining plates, and other components that require wear resistance and impact resistance. The purpose of quenching is to obtain a certain amount of bainite to ensure good comprehensive mechanical properties. The carbon content of white cast iron is generally 2.2% - 2.5%, and the content of sulfur and phosphorus should be less than 0.1%. After the heat preservation is completed at the austenitic temperature of 890 ~ 910 ℃, the required mechanical properties can be obtained by isothermal cooling in the nitrate solution of 280 ~ 300 ℃ for 90min, discharging, and air cooling.

Make a purchase of cast iron skillets for sale, cast iron conditioner, cast iron cooker from China, you can get them at a good price if you have a large quantity. We hope to be your long-term partner.