Ang email dili mahimong walay sulod

Ang password dili mahimong walay sulod

Sayop sa format sa email

Ang email dili mahimong walay sulod

Anaa na ang email

6-20 ka karakter (mga letra ug numero lamang)

Ang password dili managsama

Sayop sa format sa email

Ang email dili mahimong walay sulod

Wala ang email

6-20 ka karakter (mga letra ug numero lamang)

Ang password dili managsama

Balita

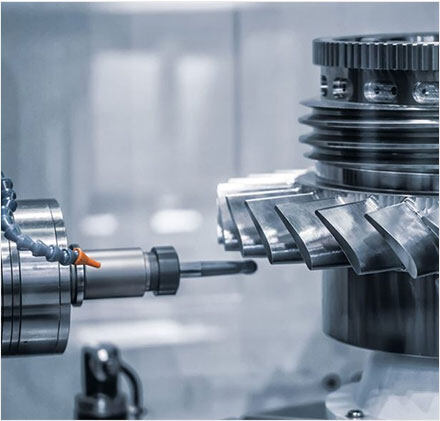

Difference Between Precision Sheet Metal Processing and Ordinary Sheet Metal Processing

In recent years, with the improvement of the market requirements for the precision of sheet metal parts, precision sheet metal processing has also begun to enter the center of the sheet metal industry.

As a key production process in the machinery manufacturing industry, precision sheet metal parts are widely used in rail transit equipment, precision machine tools, automobile manufacturing, medical devices, household appliances, etc., which is an important embodiment of China's intelligent manufacturing. So what is the difference between precision sheet metal processing and ordinary sheet metal processing?

Difference between precision sheet metal processing and ordinary sheet metal processing

From the perspective of development history, precision sheet metal is an advanced version of sheet metal processing, and the process changes little. The biggest difference is that precision sheet metal processing reduces the accuracy tolerance range to less than 0.2mm, while the accuracy of ordinary sheet metal processing is generally between 0.2~1mm.

The tolerance range of high-precision sheet metal processing: curvature: 0-+/-0.1mm; NC machining: 0-+/-0.1mm; Laser cutting 0-+/-0.1mm.

The uncoiling and leveling accuracy of precision sheet metal processing can reach 0.3 ~ 0.5mm, so the sheet metal parts cut by laser / digital punch/water jet and produced by NC bending can usually meet the dimensional accuracy requirements.

The sheet metal processing process has gone through three stages: from scribing with compasses, scissors, wood squares, and other tools, to hydraulic plate shears and bending machines with labor-saving parts processing and uniform surface quality after processing, and then to today's CNC processing equipment, the bending angle of processed parts can be accurate to 0.1 °, and the size can be accurate to 0.1mm or even higher, There is no need to use trapezoidal screw or thread to adjust the positioning a little or even several times as before, to save a lot of time and materials for the manufacturing of sheet metal machined parts.

Precision sheet metal processing technology

Precision sheet metal adopts high-precision CNC sheet metal equipment, which can realize the complex process that traditional sheet metal processing is difficult to achieve, and precision sheet metal processing is also suitable for the processing of large and small batches of products, and has the characteristics of the short processing cycle, good uniformity, high processing precision, high automation, high speed, simple and convenient operation, high efficiency and so on.

Characteristics of precision sheet metal processing

- High power density of sheet metal processing: after the workpiece absorbs sheet metal processing, the temperature rises rapidly and melts or evaporates. Even materials with a high melting point, high hardness, and brittleness can be processed with precision sheet metal;

- Convenient and flexible sheet metal processing: robots can be used for precision sheet metal processing in harsh environments or places inaccessible to others;

- Sheet metal processing is easy to control: it is easy to combine with precision machinery, precision measurement technology, and electronic computers to achieve high machining automation and high machining accuracy.

Surface treatment methods for precision sheet metal processing: galvanizing, chromium plating, painting, electrostatic powder spraying.

Most precision sheet metal parts in the market have textures on their surfaces. These textures are obtained after surface treatment, which can effectively protect sheet metal parts from external factors, corrosion, denaturation, and so on.

Searching for advance precision machining, cnc precision machining services, precision machining shop in China, you can get high-quality products at a nice price.