Ang email dili mahimong walay sulod

Ang password dili mahimong walay sulod

Sayop sa format sa email

Ang email dili mahimong walay sulod

Anaa na ang email

6-20 ka karakter (mga letra ug numero lamang)

Ang password dili managsama

Sayop sa format sa email

Ang email dili mahimong walay sulod

Wala ang email

6-20 ka karakter (mga letra ug numero lamang)

Ang password dili managsama

Balita

7 Amazing Applications of Customized CNC Processing(2)

-

Consumer electronics industry

In addition to large components, CNC processing can also produce small and fine arts for the electronic industry on a large scale. CNC processing technology helps to produce plastic and metal processing components for consumer electronics, such as circuit boards, which may require lasers to achieve detailed accuracy.

Some manufactured electronic components include capacitors, radiators, amplifier housings, circuit chips, diodes, transistors, and capacitors for computers, televisions, radios, and smartphones.

Customized CNC machining meets the high tolerance of small parts and maintains zero error in the micro machining process. This technology is also very reliable because it can produce large quantities of electronic parts in a short time without affecting the quality.

-

Automobile industry

Due to its production speed and accuracy, CNC machining has become so common in the automotive industry. The automotive industry is known for its consistency and high manufacturing rates.

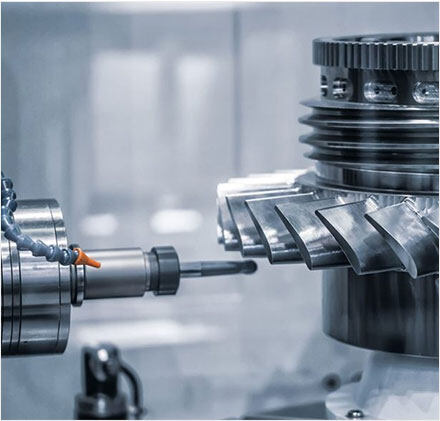

Custom CNC machines have a wide range of functions, can handle everything from simple shafts to solid turbine blades, and are responsible for the speed and quality required by the industry.

Because the automobile industry is dominated by speed, many complex parts such as engine block, gear, braking system, piston, and gearbox need quality and higher accuracy. Any deviation will lead to faster wear.

CNC machining also helps the automotive industry achieve rapid model changes by accelerating the testing, research, and development of necessary prototypes.

-

Marine industry

In addition to dry land, CNC processing promotes ships of all sizes to cruise on global waterways by manufacturing complex ship materials that help ship machines stay afloat. Unlike other departments, ships need waterproof components to withstand long periods of stay in the water and humid environments. This includes furniture for luxury yachts and sailboats, fishing boats, and large cruise ships. The components in these containers require special manufacturing considerations to prevent moisture corrosion and the effects of salt water.

Custom CNC processing produces suitable and durable ship parts, such as propeller, insulation box, ship parts, prototype mold, and electronic and engine parts.

-

Aerospace Industry

In addition to speed, safety is another key factor to pay attention to when producing aircraft-related systems. Whether engaged in space-related commercial projects or military projects, aviation engineers need to manufacture all aircraft components to the highest standards.

The high precision requirements and high level of tolerance and durability in the aerospace field make custom CNC machining an important manufacturing process.

This processing technology can achieve super tight tolerance and durability for metal and plastic materials used in aircraft assembly while taking advantage of the key characteristics of Aerospace: weight and strength.

CNC processes and manufactures customized light aircraft parts, such as manifolds, antennas, wings, landing gear parts, RF suppression components, and bushings.

We are a low volume cnc machining, small batch cnc machining near me, rapid prototyping cnc machining exporter supplier wholesaler, our products satisfy our customers. And we want to be your long-term partner, any interests, welcome to contact us.